Our Services

Warehousing

For Alpha Nautical Logistics, understanding our client’s needs is essential in our planning and allocation of the various storage solutions required in support of Exploration & Drilling (Rig), and transitioning through to Production (FPSO) Support.

Warehouse Layout

• Heavy Racking – 2400kg/Bay/Palletised

• Light Racking – Lin Bins

• Temperature Controlled Storage – Lin Bins

• Goods Receiving Area

• Stuffing and Dispatch area

• Covered Overhang/Outside storage – Very Large items

• Light Racking – Lin Bins

• Temperature Controlled Storage – Lin Bins

• Goods Receiving Area

• Stuffing and Dispatch area

• Covered Overhang/Outside storage – Very Large items

Warehouse Processes

• Goods Receiving/QAQC/Binning (SAP or nominated

WMS/ ERP Solution)

• Dispatch/Picking/Stuffing/Manifesting/Customs Clearance (CCU Tracking)

• RLM/Rig returns/Non-Stock

• Inventory Management/Stock counts

• Preservation

• Dispatch/Picking/Stuffing/Manifesting/Customs Clearance (CCU Tracking)

• RLM/Rig returns/Non-Stock

• Inventory Management/Stock counts

• Preservation

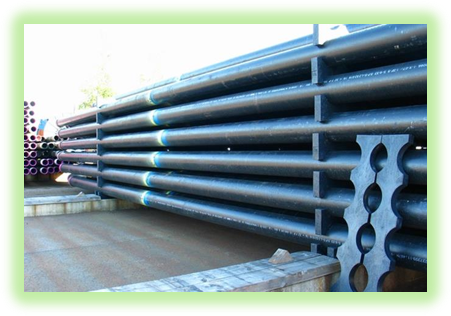

OCTG Storage and Handling (Tubulars 4 1/2” to 30”)

For Alpha Nautical Logistics, understanding our client’s OCTG storage and draw down is essential in our planning and allocation of the stacking solutions required in support of Exploration & Drilling.

OCTG Storage Layout

• Proposed area of initial 5 000m2 to 10 000m2

• Aggregate stone base footing (No concrete)

• Overlaid with Cellpave – LDPE recycled matting system

• Infilled with crushed aggregate stone

• High load bearing stable laydown area

• Suitable for OCTG stacking and storage of large items

• Aggregate stone base footing (No concrete)

• Overlaid with Cellpave – LDPE recycled matting system

• Infilled with crushed aggregate stone

• High load bearing stable laydown area

• Suitable for OCTG stacking and storage of large items

OCTG Handling Processes

• Unbundling at laydown area

• Racking on Fix Flex Pipe Carriers

• Pipe Inspection Bay

• Lashing for loadout to PSV

• Racking on Fix Flex Pipe Carriers

• Pipe Inspection Bay

• Lashing for loadout to PSV

COSHH storage and decanting

For Alpha Nautical Logistics, understanding our clients offshore Chemical requirements and safe handling offers COSHH storage and Decanting services with industry safety standards.

(COSHH – Control of Substances Hazardous to Health)

• Storage of various chemicals in IBC containers.

• All IBC Containers stored on Steel Bunded trays to mitigate any spillage incidents.

• Safety – Hazmat Suites and Washdown stations for personnel

• Pumping arrangements are Pneumatic (Compressor driven)

• Offshore CCU Tote Tanks are DNV certified

• Risk Assessments carried out with consultation of MSDS

• IBC stored in complaint segregated manner with regard to various chemical types.

• All IBC Containers stored on Steel Bunded trays to mitigate any spillage incidents.

• Safety – Hazmat Suites and Washdown stations for personnel

• Pumping arrangements are Pneumatic (Compressor driven)

• Offshore CCU Tote Tanks are DNV certified

• Risk Assessments carried out with consultation of MSDS

• IBC stored in complaint segregated manner with regard to various chemical types.

Heavy Lift Transportation and Reel storage

For Alpha Nautical Logistics, understanding our clients Heavy Lift and reception and load out of Sub-sea Reels is meticulously planned by ANL and our Heavy Lift Specialist partner.

All lift plans are LOLER compliant and submitted to CPY Subject Matter Expert for verification.

ANL offers the design and engineering service for the required Beams & Stools needed for long-term storage away from the quay and easy access when needed.

All lift plans are LOLER compliant and submitted to CPY Subject Matter Expert for verification.

ANL offers the design and engineering service for the required Beams & Stools needed for long-term storage away from the quay and easy access when needed.

Heavy Lift Handling

• Lift Plans

• Route plans

• SPMT – Self Propelled Modular Transporter

• Jacking and Skidding

• Route plans

• SPMT – Self Propelled Modular Transporter

• Jacking and Skidding

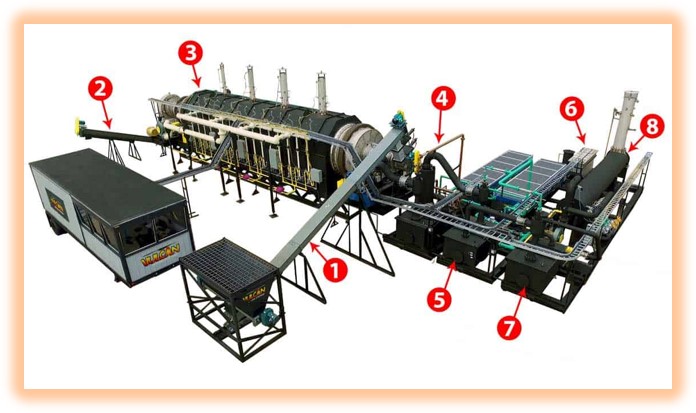

TDU services and Waste Management

For Alpha Nautical Logistics, we offer Waste Management Services for General waste / Hazardous waste and TDU (Thermal Desorption Unit) for the specialised treatment of Offshore waste including drill cutting and pigging sludge.

Through out Waste Management partner only approved technology and equipment is employed in these processes.

Offshore waste skips for general, as well as Hazardous waste and cuttings, are DNV approved CCU’s which will rotate through the treatment plant for processing and cleaning prior to returning offshore.

Vessel tank cleaning via skid mounted system, driving up to 6 tank cleaning machines is a service that ANL can offer for the cleaning of PSV tanks carrying Water based and Oil based muds. (WBM & OBM)

Through out Waste Management partner only approved technology and equipment is employed in these processes.

Offshore waste skips for general, as well as Hazardous waste and cuttings, are DNV approved CCU’s which will rotate through the treatment plant for processing and cleaning prior to returning offshore.

Vessel tank cleaning via skid mounted system, driving up to 6 tank cleaning machines is a service that ANL can offer for the cleaning of PSV tanks carrying Water based and Oil based muds. (WBM & OBM)

LMP Services (Liquid Mud Plant)

For Alpha Nautical Logistics, we are in negotiations with Liquid Mud

Plant operators and suppliers to present a LMP that has the correct

capacity and fit for purpose in support of a Drilling Campaign.

By understanding the Drilling program and the required tank capacities we will be well positioned to offer a LMP that aligns with the Drilling campaign.

By understanding the Drilling program and the required tank capacities we will be well positioned to offer a LMP that aligns with the Drilling campaign.

Price per Ton Model for Supply Base Services

For Alpha Nautical Logistics, we can depart from the Industry price

listing type billing which has dominated the industry for decades and

offer a price per ton model for Warehousing and Supply Base

services* for the day-to-day activities associated with operating a

supply base.

Information around this pricing structure is based on the principal whereby the CPY commits to a minimum through put tonnage that will be expected over a 3 to 5 year period, on an annual basis with growth projections.

Information around this pricing structure is based on the principal whereby the CPY commits to a minimum through put tonnage that will be expected over a 3 to 5 year period, on an annual basis with growth projections.

This price per ton model can include:

• Goods Receiving/QAQC/Picking/Stuffing

• Warehouse space rental

• Warehouse staff

• Quayside staff

• 1x Crane of agreed size, Forklift trucks , Flat bed trucks

• Covers items that can fit into standard CCU’s.

• Measured Tonnage on the Crane Hook – Inbound and Outbound.

• Excludes – Bulks/OCTG/COSHH/Heavy lift handling

• CPY has an upfront clear costing, with regard to the standard supply base offering.

ANL look forward to discussing and finding a winning solution, to this initiative.

• Warehouse space rental

• Warehouse staff

• Quayside staff

• 1x Crane of agreed size, Forklift trucks , Flat bed trucks

• Covers items that can fit into standard CCU’s.

• Measured Tonnage on the Crane Hook – Inbound and Outbound.

• Excludes – Bulks/OCTG/COSHH/Heavy lift handling

• CPY has an upfront clear costing, with regard to the standard supply base offering.

ANL look forward to discussing and finding a winning solution, to this initiative.

Cost Efficiency Model

The Aim of Cost Efficiency Models

To provide Cost Efficiency Models to create significant cost savings to IOC Clients. This will be achieved by alignment and agreement between the parties to collaborate with ANL on various Cost Efficiency Models.

All IOC are seeking long term cost saving initiatives as the focus shifts to optimisation and long -term sustainability. This can be achieved by Cost Efficiency Models.

To provide Cost Efficiency Models to create significant cost savings to IOC Clients. This will be achieved by alignment and agreement between the parties to collaborate with ANL on various Cost Efficiency Models.

All IOC are seeking long term cost saving initiatives as the focus shifts to optimisation and long -term sustainability. This can be achieved by Cost Efficiency Models.

The Benefits of Cost Efficiency Models

• Large % Cost reduction for same Annual Tonnage delivered.

• Supply Base Costs – Upfront Fixed known cost against nominated Tonnage amount using the Price/Ton Model – No Scope Creep as all services are included.

• Clear robust governance arrangements are in place between Company and Contractor.

• Formalised Contracts outlines each party’s obligations.

• Strong engagement and support by senior management at all stages of a project.

• Senior management from all parties buy in and support the cost cutting initiative.

• A thorough understanding of baseline performance and costs.

• Monitoring of the benefits of cost efficiency models through agreed KPI’s.

• Efficient, standardised processes and reporting structures.

• Pay per Use Services

• Supply Base Costs – Upfront Fixed known cost against nominated Tonnage amount using the Price/Ton Model – No Scope Creep as all services are included.

• Clear robust governance arrangements are in place between Company and Contractor.

• Formalised Contracts outlines each party’s obligations.

• Strong engagement and support by senior management at all stages of a project.

• Senior management from all parties buy in and support the cost cutting initiative.

• A thorough understanding of baseline performance and costs.

• Monitoring of the benefits of cost efficiency models through agreed KPI’s.

• Efficient, standardised processes and reporting structures.

• Pay per Use Services

Cargo Carrying Units – CCU – Pay per use

Offshore CCU’s – ANL Managed CCU Services – Pay per Use Basis

• ANL will contract with CCU providers (Swires, Cavmont, Librod) for

the supply of Offshore CCU’s, mobilised to Namibia – ANL Supply

Base.

• CCU’s are available at ANL Base for client use and will be managed and tracked by ANL.

• Through planning and tracking ANL offer the saving of charging for CCU’s on a pay per use basis, with units being on-hired/off hired as and when they are used.

• On hired – 2 days prior to departing the Supply Base (For Stuffing, Lashing and Manifesting)

• Off hired – 4 days after return to Supply Base (For Unstuffing, Re- Integration, Returns processing and cleaning as required.

• CCU’s are available at ANL Base for client use and will be managed and tracked by ANL.

• Through planning and tracking ANL offer the saving of charging for CCU’s on a pay per use basis, with units being on-hired/off hired as and when they are used.

• On hired – 2 days prior to departing the Supply Base (For Stuffing, Lashing and Manifesting)

• Off hired – 4 days after return to Supply Base (For Unstuffing, Re- Integration, Returns processing and cleaning as required.

Marine Transportation

For Alpha Nautical Logistics, we have aligned ourselves with a world

leading shipyard that offers modern vessels with class leading

solutions for various types of vessels used in the offshore industry.

ANL focuses on providing innovative proposals to drive down costs based on singular or shared vessel services* using locally flagged vessel with high local content initiatives.

ANL focuses on providing innovative proposals to drive down costs based on singular or shared vessel services* using locally flagged vessel with high local content initiatives.

Nominated vessels include:

• Platform Supply Vessel (Large PSV) 900m2 – 1000m2 Deck space

• Fast Support Intervention Vessels (FSIV) up to 35 knots

Inclusive of:

Up to 120 seats for Offshore crew Ampelman Heave Compensated Gangway Gyro stabilized

These vessels can be employed in collaboration with other operators who are in the similar geographic location whereby vessel day rate, fuel and port charges are apportioned on agreed principals. Eg: Price per mile, price per m2 deck space

• Fast Support Intervention Vessels (FSIV) up to 35 knots

Inclusive of:

Up to 120 seats for Offshore crew Ampelman Heave Compensated Gangway Gyro stabilized

These vessels can be employed in collaboration with other operators who are in the similar geographic location whereby vessel day rate, fuel and port charges are apportioned on agreed principals. Eg: Price per mile, price per m2 deck space

Vessel Shared Service – “Milk Run” Model

Shared Service Vessels: “Milk Run” Type Model.

Operation of PSV’s or similar, are inherently un-economical and underutilised assets due to various factors (Weather/Standby). By utilising a Shared Vessel/s Services – ANL can plan and co-ordinate each Companies’ requirements for offshore delivery in an agreed sequence. With CCU on ground and ready for loading, the PSV can be quickly turned around for a weekly “Milk run” to various offshore assets.

Currently vessels are time chartered to each Company, resulting in vast hours of underutilised idle time and market related day rate fluctuations. ANL proposes providing the vessel solution and sharing the costs between several clients based on an agreed method.

Operation of PSV’s or similar, are inherently un-economical and underutilised assets due to various factors (Weather/Standby). By utilising a Shared Vessel/s Services – ANL can plan and co-ordinate each Companies’ requirements for offshore delivery in an agreed sequence. With CCU on ground and ready for loading, the PSV can be quickly turned around for a weekly “Milk run” to various offshore assets.

Currently vessels are time chartered to each Company, resulting in vast hours of underutilised idle time and market related day rate fluctuations. ANL proposes providing the vessel solution and sharing the costs between several clients based on an agreed method.

Methods to consider will include:

• Base Operator – Price per handled ton at ANL Base.

• Vessel charges

ANL to provide fixed Base case for vessel availability.

Utilisation:

• Price per ton

• Price per Nautical Mile

• Price per m2 – deck space

• Shared Namport charges apportioned to Client Loads

• Shared fuel charges apportioned to client - Location/Milage/Utilisation

• Adjacent is an example of a Vessel Shared Services Model between 3 clients, demonstrating the Cost Saving, based on a weekly “Milk Run” to Client locations, using 1x Large PSV.

• Note: Currently each IOC is chartering its own vessels, so the actual vessel spend is 3x what is indicated for the 1 Large PSV. (Assumed 52000 tons of IN/OUT Cargo)

• Vessel charges

ANL to provide fixed Base case for vessel availability.

Utilisation:

• Price per ton

• Price per Nautical Mile

• Price per m2 – deck space

• Shared Namport charges apportioned to Client Loads

• Shared fuel charges apportioned to client - Location/Milage/Utilisation

• Adjacent is an example of a Vessel Shared Services Model between 3 clients, demonstrating the Cost Saving, based on a weekly “Milk Run” to Client locations, using 1x Large PSV.

• Note: Currently each IOC is chartering its own vessels, so the actual vessel spend is 3x what is indicated for the 1 Large PSV. (Assumed 52000 tons of IN/OUT Cargo)

Aviation Transportation

Alpha Nautical has partnered with a leading offshore aviation company –

Caverton helicopters.

Caverton Helicopters Limited is one of the largest aviation logistics support company in West Africa, with over 22 years’ experience providing fixed wing and rotary wing services to the oil and gas industry. The company currently operates a mixed fleet of 28 aircraft across multiple locations in Nigeria and West Africa.

Since inception, Caverton has successfully operated for major International Oil Companies (IOC) with a combined contract value of over (US) $3.5bn . Caverton operates out of several facilities across Nigeria including a 10,000sqm flight facility and a 40,000sqm hangar facility in Lagos. Caverton also operates a base in Cameroon and has strong operational presence in the Republic of Benin.

Caverton Helicopters Limited is one of the largest aviation logistics support company in West Africa, with over 22 years’ experience providing fixed wing and rotary wing services to the oil and gas industry. The company currently operates a mixed fleet of 28 aircraft across multiple locations in Nigeria and West Africa.

Since inception, Caverton has successfully operated for major International Oil Companies (IOC) with a combined contract value of over (US) $3.5bn . Caverton operates out of several facilities across Nigeria including a 10,000sqm flight facility and a 40,000sqm hangar facility in Lagos. Caverton also operates a base in Cameroon and has strong operational presence in the Republic of Benin.

Aviation Services:

• Maintenance.

• Bonded Stores and Spares.

• Training and Local Content Development

• Bonded Stores and Spares.

• Training and Local Content Development